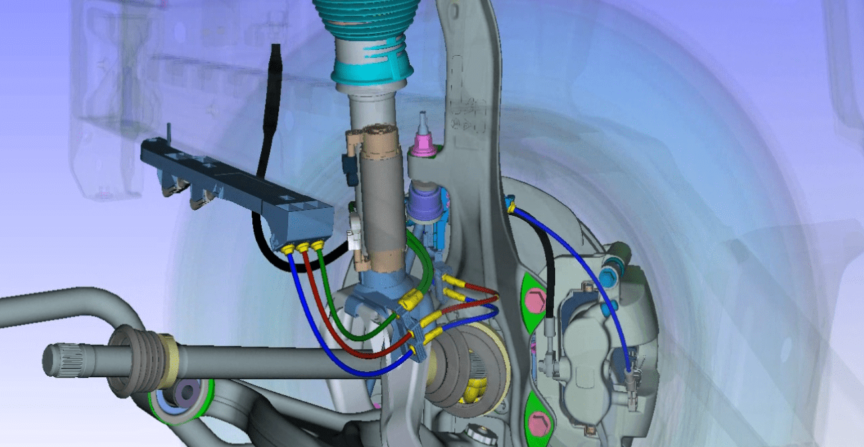

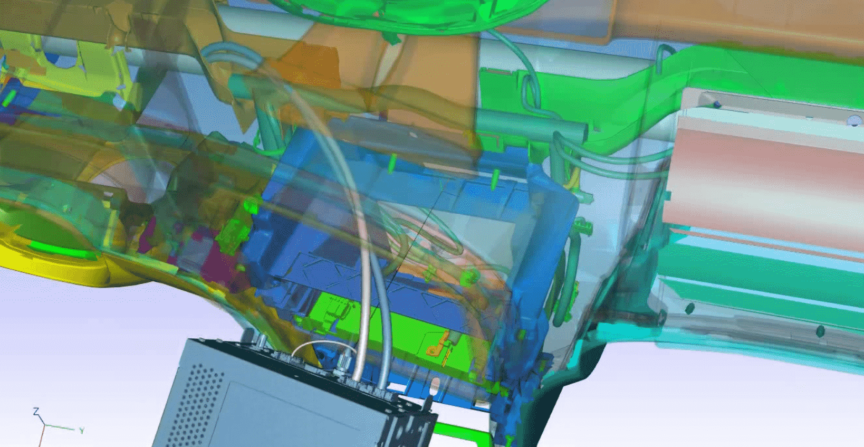

Cable installation in the wheel arch

– Situation: There are increasing functions which need to be built into small spaces of the wheel arch, e.g. wheel rotation sensors, electronic parting brakes or damper controls. It requires accordingly many cables, which must be installed. ... See more

“This increasing complexity in the wheel arch gave us the idea for a software application that visualises the optimal routing of the cables” (Matthias Mehnert, Head of the Coroplast Service Center in Großmehring)

– Coroplast explains: “IPS simulation software realistically reflects the situation in the assembly space three-dimensionally in the form of animations, making it possible to calculate points of contact, collision and high stress with great precision. The technology also enables bending radii, applied forces, rotations and tensions to be analysed and optimised on the basis of the simulation data”

– Result: “Development progresses faster, as fewer prototypes have to be built and fewer iterations are needed. In short, the software saves both time and costs” (Coroplast, 2019)

See less